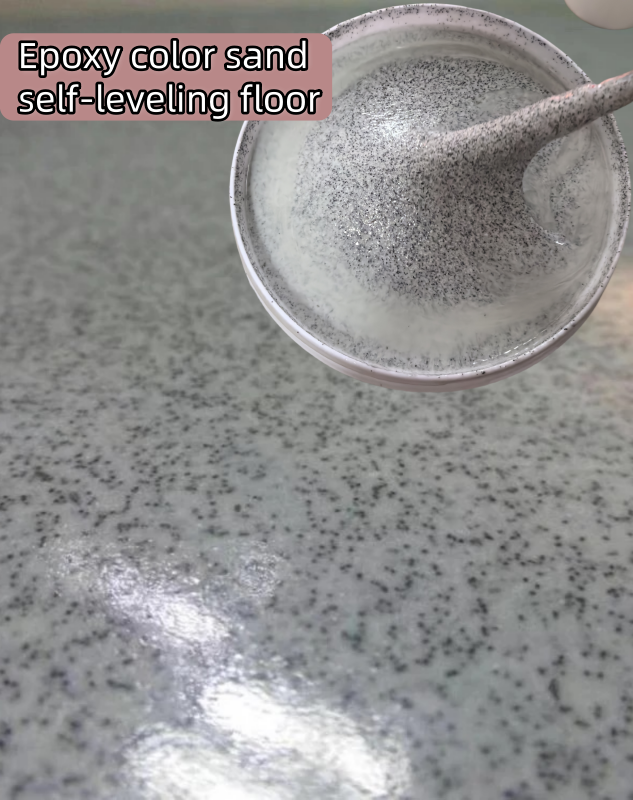

Self Leveling Color Sand Epoxy Floor Top Coating

Product introduction:

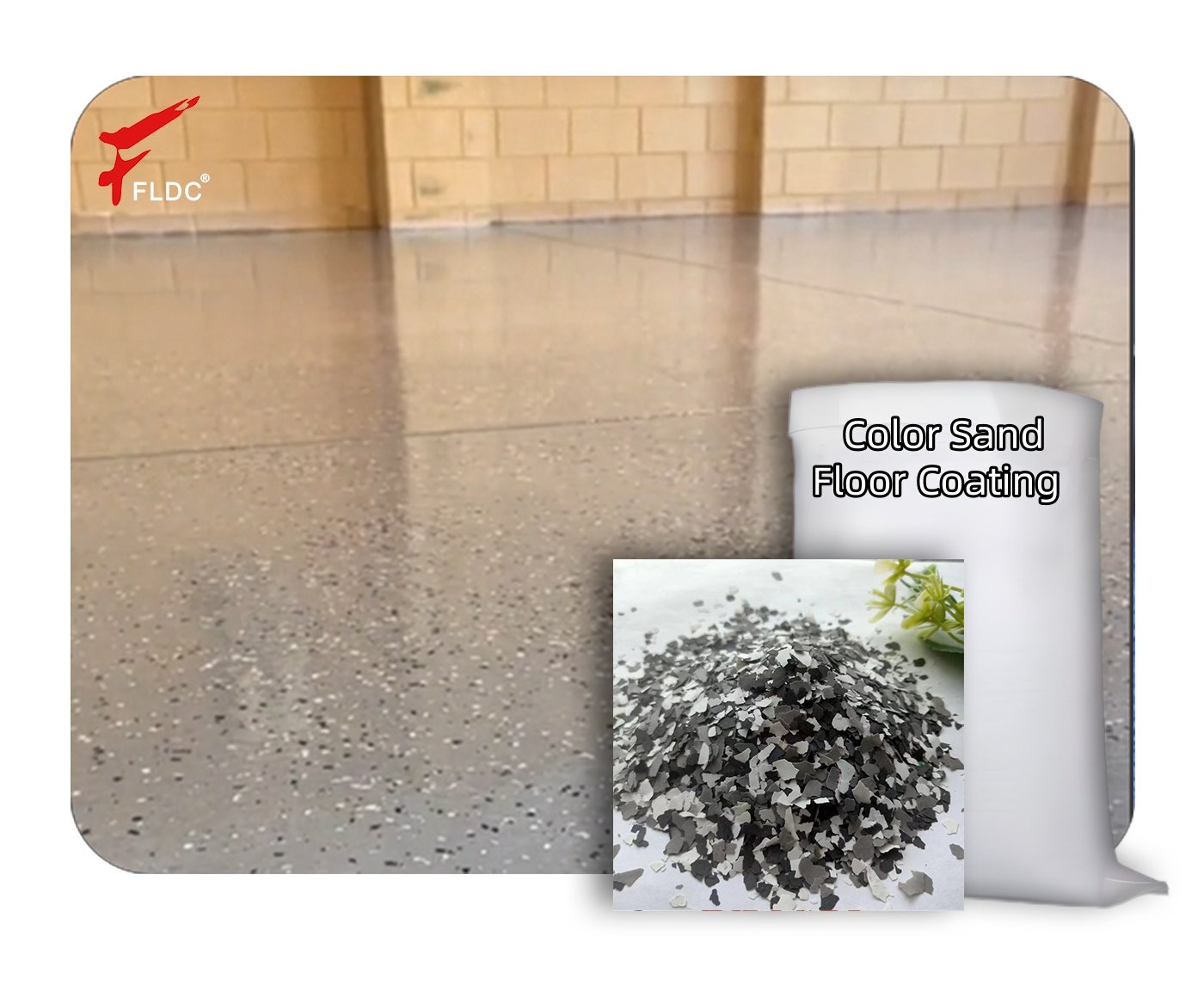

Epoxy color sand flooring is a versatile and visually appealing flooring solution that combines the durability of epoxy resin with the decorative touch of colored quartz sand. This seamless flooring system offers not only a robust and long-lasting surface but also adds a vibrant aesthetic to various spaces.

Application scope:

Application scope:

1, electronic communications, cigarette factories, food factory, health care, petrochemical, textile, furniture, office accessories, and other industries, the need to co

mpressive, impact resistance, abrasion resistance and requirement on the ground without even seam, high clean place.

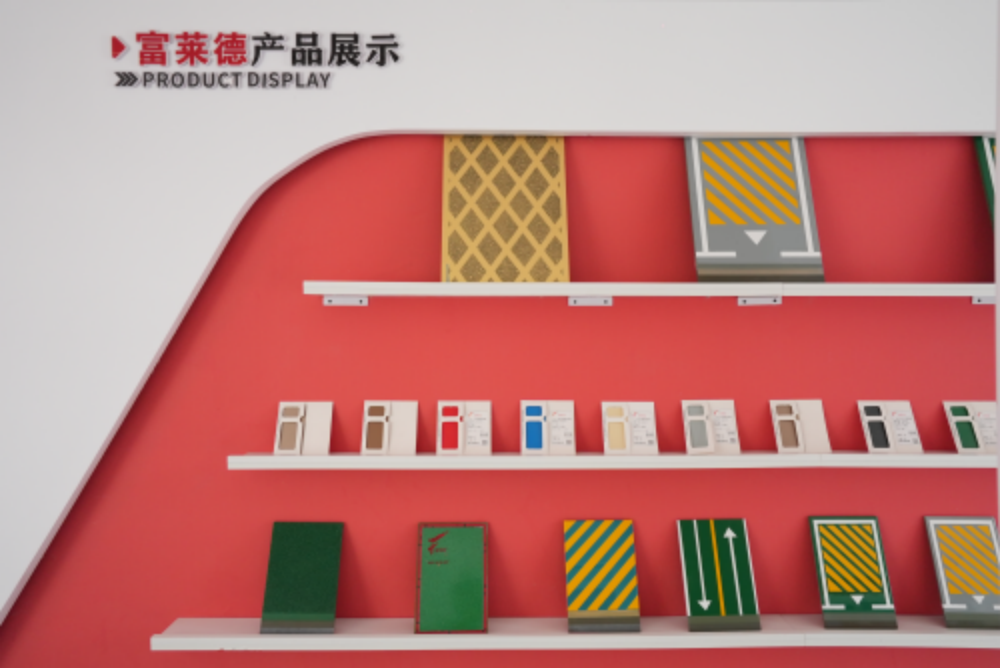

2, high-grade entertainment, hotel, airport, subway, shopping malls, commercial buildings, exhibition center, office and lab attaches great importance to the aesthetic effect, at the same time,higher requirements on the abrasion resistance to pressure.

Material advantages:

1, the product has: a whole shape, no seams, environmental protection, low viscosity, excellent colour retention, flow and good flowing property, coating high hardness, excellent abrasion resistance, impact resistance, excellent strength;

2, compared with the original manual pressure sand texture is more low raw material cost per unit area and save labor, save time, without a professional large equipment, can be thin film forming, etc.

7 Step Guide on How to Apply epoxy color sand self leveling floor

Step 1. Preparing the surface before applying the epoxy

Step 2. Sweeping and cleaning of the floor

Step 3. How to Apply Epoxy: Prime the floor with a suitable epoxy primer

Step 4. Fill all cracks, holes etc with epoxy grout.

Step 5. Application of the first coat of epoxy paint

Step 6. Final Sanding and Filling before applying the final epoxy floor paint

Step 7 Apply the final coat.

Construction Conditions:

1. Substrate requirements

The painted surface of architectural coatings must be dry, firm, clean and smooth;

Dry: the floor humidity is lower than 6%RH, and the PH value is less than 10;

Firmness: no loose powder, no loose patent leather on the old ground;

Clean: Free of oil, grease, mildew, algae and other adherents.

2. Construction environment:

The ground temperature should not be lower than 5ºC, and the ambient humidity should be lower than 85%RH to ensure good film formation.

3. Construction precautions:

This product can be appropriately added with diluent depending on different construction methods and construction environments, but the dilution ratio should be strictly controlled. Excessive dilution of the main agent and curing agent must be mixed in the correct proportion. The main agent should be mixed with an electric mixer first. Then slowly add the curing agent and stir well.

Reviews

There are no reviews yet.