what is solvent free epoxy, and the solvent based epoxy primer data sheet:

HDDD-502 Solvent-Free

Overview: Solvent-free epoxy sealing primer is a two-component coating that uses epoxy resin as the main film-forming material and is mixed with an amine curing agent.

Key Features:

- Excellent Permeability and Sealing Resistance: Provides a robust barrier against contaminants.

- Superior Adhesion: Ensures strong bonding with subsequent coatings like epoxy and polyurethane paints.

- Alkali and Water Resistance: Protects surfaces from alkali and water damage.

- Water and Salt Water Resistance: Offers additional protection in moist or marine environments.

- Environmentally Friendly: VOC-free, reducing environmental impact.

- Quartz Powder Compatibility: Can be mixed with quartz powder for intermediate coatings or caulking.

- Application Flexibility: Used as a sealing primer on cement-based surfaces and as a mid-coat with quartz sand.

Applications: Ideal for sealing primer applications on cement-based surfaces. Also suitable for use with quartz sand as a mid-coat or for caulking purposes.

Technical Specifications:

| Attribute | Description |

|---|---|

| Color | Transparent, slightly yellow. |

| Volume solid content | ≥98% |

| Drying Time | Surface dry ≤6h, Hard dry ≤24h (at 25ºC) |

| Specific Gravity | 150g-200g/square meter |

| Flash Point | 38ºC |

Construction Parameters:

- Curing Time: New cement base surfaces must be cured for more than 28 days.

- Surface Preparation: Mechanically polish cement to roughen, absorb floating dust, and ensure cleanliness.

- Environmental Conditions: Avoid construction when ground moisture is below 5%, air humidity exceeds 85%, or temperature is below 5ºC.

- Usage Time: Use the paint within half an hour of preparation to prevent gel waste.

- Dilution: For use as a middle coating with sand, epoxy diluent can be added if viscosity is too high; diluent amount should not exceed 80% of the total.

- Reaction Speed: Faster reaction at higher temperatures, shortening operation time.

- Application Method: Scraping or rolling.

- Packaging:Component A: 20L barrel, 24kg/backet.

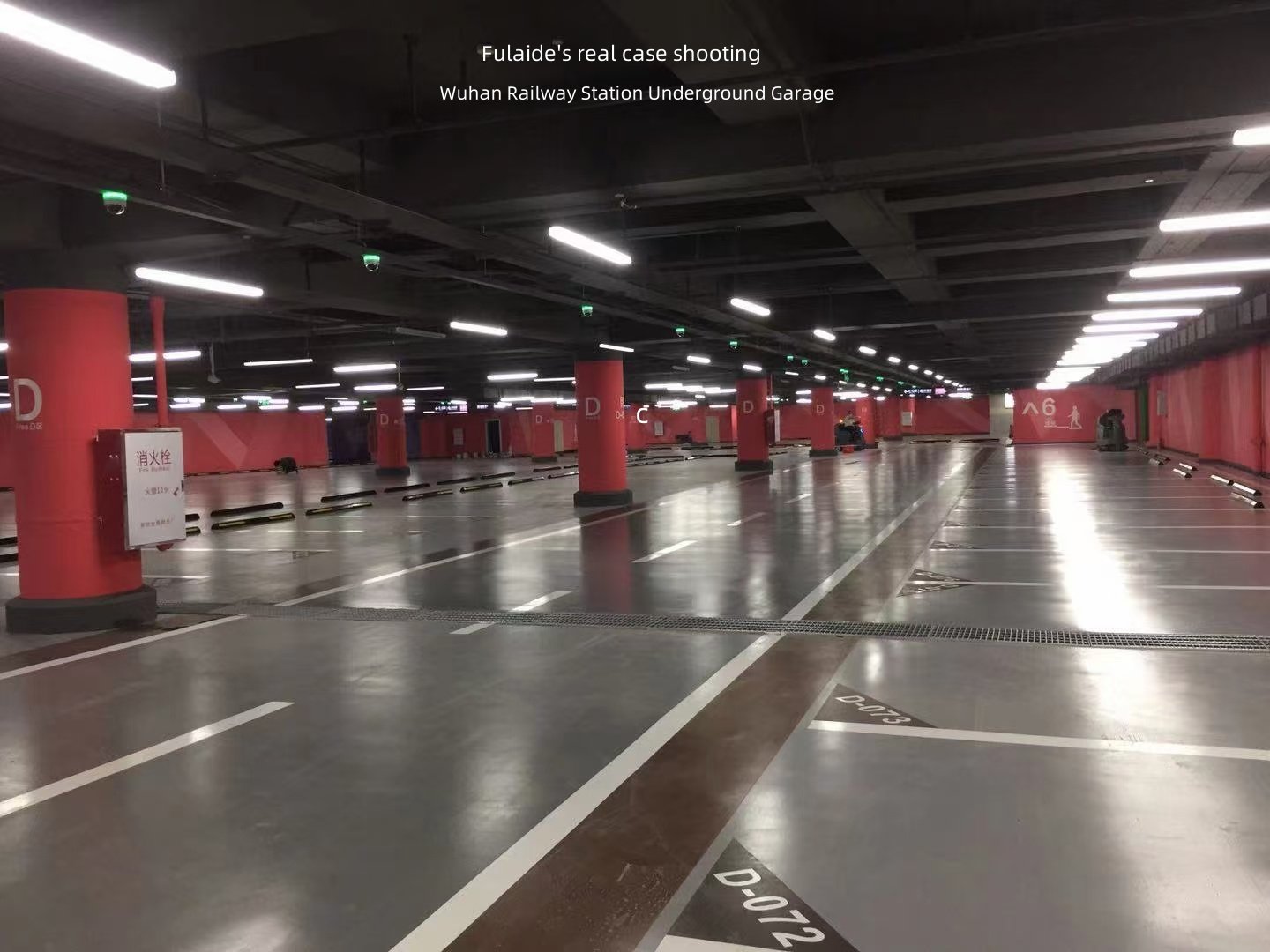

Component B: 4L square can, 4kg/can. Hubei Fulaide Co., Ltd. wfounded in 2001. It is a national high-tech  enterprise dedicated to the research and development, production and service of coatings. It has outstanding product research and development in the fields of industrial protection, bridge coating, green oxygen resin floor, special functional coatings, etc.

enterprise dedicated to the research and development, production and service of coatings. It has outstanding product research and development in the fields of industrial protection, bridge coating, green oxygen resin floor, special functional coatings, etc.

- Over the past 20 years, hundreds of national key projects have selected Fulide coatings, exported to more than 10 countries and regions, serving 30,000+ customers, widely covering bridges, electricity, electronics, construction, medicine, petrochemicals, stadiums, machinery, auto parts and other industries and fields, with a coating coverage of more than 5,000,000 square meters. Become a long-term cooperative supplier and service provider for China Power Construction, China Railway, China Communications, China Minmetals, China Energy, China Construction, China Emergency Equipment and other Fortune 500 companies and military enterprises such as 94825, 35825, 380425.

- In 2019, Fulide coatings have excellent quality, and Fulide became the preferred coating brand for the construction of the 7th World Military Games.

Reviews

There are no reviews yet.